Frequency Converter& Automation

EFYN Frequency Converters

Every Frequency You Need

EFYN are frequency converters capable of handling conversion between different grid standards, typically from 50 Hz to 60 Hz and vice versa. This allows powering equipment, accessories, and small appliances for guests and crew without the need for external adapters.

Thanks to the integrated Active Front End (AFE) technology, EFYN not only convert frequency but also improve the power quality drawn from the yacht’s main bus, ensuring:

- Pure Sine Wave Output: Provides clean and stable energy, protecting sensitive electronic devices.

- Galvanic Isolation: The output is fully isolated to protect equipment from interference and potential ground faults.

- Interference Reduction: AFE minimizes power disturbances and harmonics, ensuring interference-free operation.

Key Advantages and Features

EFYN combine high performance and reliability, offering a complete solution for onboard frequency management:

- Reliability and Performance: Designed to provide stable power supply even in the presence of voltage or frequency disturbances.

- Operational Efficiency: High AFE efficiency helps reduce operating costs.

- Safety: RFI protection, galvanic isolation, and low earth leakage safeguard sensitive equipment and users.

- Robustness: High overload capacity and robust air cooling in an IP43-rated cabinet allow continuous and reliable operation up to 45°C.

- Intuitive Control: Digital touchscreen displays enable immediate system monitoring and management.

- Quiet Operation: Optimized design ensures silent performance, enhancing onboard comfort

Technical specifications

18kW EFYN MODEL

- Dimension: 1200 x 400 x 400

- Input: 400 Vac 50 Hz (3F)

- Output: 120 Vac 60 Hz ( 3F+ N)

- Power: 18kVA

- Three-phase copper-wound transformer: I1 38A @270 v , I2 87A @120 V

TECHNICAL FEATURES

- Power: From 12Kv

- Input Frequency: 50 or 60 Hz

- Output Frequency: 50 or 60 Hz

- Input Voltage: 120–480 Vac, 3-phase, 50/60 Hz

- OutPut Voltage: 120–480 Vac, 3-phase, 50/60 Hz

- Cooling: Forced

- Out Isolation Trasformer: Yes

- Connection: Terminal Block

- Display and Alarm: Led or LCD

(Other options available on request)

Onboard Automation

We develop automation systems for the control of onboard components, including benches, tables, and hatches. Our technology is based on the integration of linear actuators, dedicated PLCs, and intuitive HMI interfaces.

For the movement of telescopic pedestals, for example, we use a low-voltage electric control system with “dead man” buttons to ensure maximum safety. The structure is made of AISI 316 stainless steel or lightweight aluminum alloys suitable for the marine environment.

Given the need for synchronous movement of multiple units (10 for the seats and 4 for the table), control is managed by two dedicated PLCs with separate circuits. Our design approach favors the use of multi-stage pedestals with minimal space requirements below deck, facilitating installation in confined areas or during the later stages of yacht construction.

Power Electronics Solutions

We design and manufacture high-performance products and solutions for the most demanding and sensitive marine applications, ensuring maximum efficiency and reliability.

When standard products do not fully meet application requirements, our expertise in power electronics, combined with extensive know-how, flexibility, and long-standing experience in the marine industry, enables us to develop highly customized solutions.

We design and build tailor-made systems for applications such as propulsion, gyroscopic and stabilization systems, and special electric motors.

- PMSM-IPM (Permanent Magnet Synchronous Motor – Internal Permanent Magnet)

- IM (Induction Motor)

- SynRM (Synchronous Reluctance Motor)

OPDE PLUS

Our drives incorporate advanced control algorithms such as MTPA (Maximum Torque per Ampere) and MTPV (Maximum Torque per Volt), maximizing motor torque efficiency under all operating conditions.

Application Fields: Ideal for systems requiring high torque, precision, and dynamic response, such as main or auxiliary propulsion systems, thrusters, and variable-speed generators.

Technical Features:

- Air or liquid cooling

- Single-phase or three-phase configurations

- Single-phase PFC stage

- 230V – 380V – 690V

- Power rating up to 1 MW

- FIELDBUS: Profinet, Ethercat, CAN Open, ModBusTCP/IP>

- FEEDBACK: Resolver, Endat, SinCos, SinCos Incremental, SinCos Absolute, Biss-B/C, Tamagawa, TLL, TLL + Hall, Hiperface DSL

Customized PowerElectronics Solutions

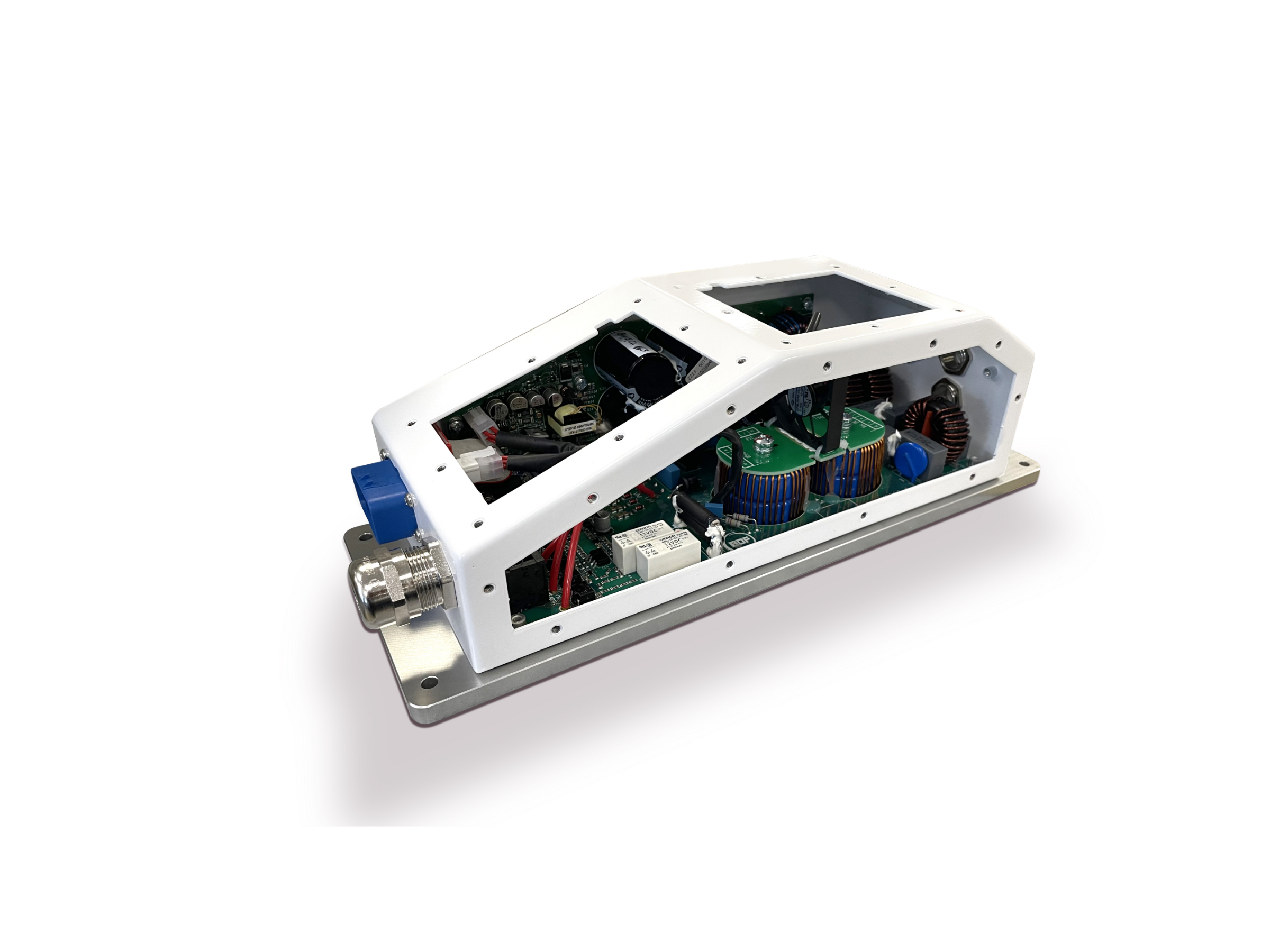

We design and manufacture high-performance custom drives for the most demanding marine applications, ensuring maximum efficiency and reliability. Our inverters are optimized for propulsion systems, gyroscopic stabilizers, and special motors. Below are some examples of recent developments:

Single-phase inverter with integrated PFC (Power Factor Correction), dedicated to powering gyroscopic stabilizers. This customized solution has been designed to provide precise and dynamic control of gyroscope rotation (up to 10,000 rpm on an 8-pole PMSM motor), ensuring high operational efficiency and low energy consumption.

Drive features include:

- Advanced Motor Control: Specific algorithms for speed and torque management, essential for stabilization, along with optimized sensorless startup for high-inertia systems.

- Single-Phase PFC Stage: Manages power conversion from single-phase shore sources (typically 120–240 V) while ensuring a near-unity power factor and low harmonic distortion on the grid.

- Power Rating: Up to 6 kW in single-phase configuration.

- Cooling: Liquid-cooled design for optimal performance and compactness even in confined spaces.

- Protection: Overvoltage, overtemperature, and short-circuit protection for uncompromising reliability.

We develop custom drives for electric propulsion systems, optimized for a wide range of motors, including:

- PMSM-IPM (Permanent Magnet Synchronous Motor – Internal Permanent Magnet)

- IM (Induction Motor)

- SynRM (Synchronous Reluctance Motor)

Our drives incorporate advanced control algorithms such as MTPA (Maximum Torque Per Ampere) and MTPV (Maximum Torque Per Volt), maximizing motor torque and efficiency across all operating conditions.

Application Field: These drives are ideal for systems requiring high torque, precision, and dynamic response, such as main or auxiliary propulsion systems, thrusters, and variable-speed generators.

Technical Features: All drives feature liquid cooling for superior thermal management, enabling a compact and robust design. Their modular architecture facilitates easy integration and maintenance on board.

Marine

RELATED PRODUCTS

Case History

Contact us!

Haven’t found what you were looking for? Contact us!