Industrial Systems

INNOVATIVE SOLUTIONS FOR INDUSTRIAL APPLICATIONS

With over 50 years of experience and a strong know-how, BDF Digital has developed advanced solutions for different types of industrial systems, integrating general communication protocols such as IRT (Industrial Real-Time) and D2D (Drive-to-Drive).

Thanks to this expertise, BDF Digital offers advanced software for managing data exchange through communication protocols, set recipes and load data. Our solutions guarantee connectivity, mobility and maximum productivity, promptly responding to the needs of Industry 4.0.

Our Systems Business Unit is present in numerous global markets, thanks to the experience acquired as a System Integrator.

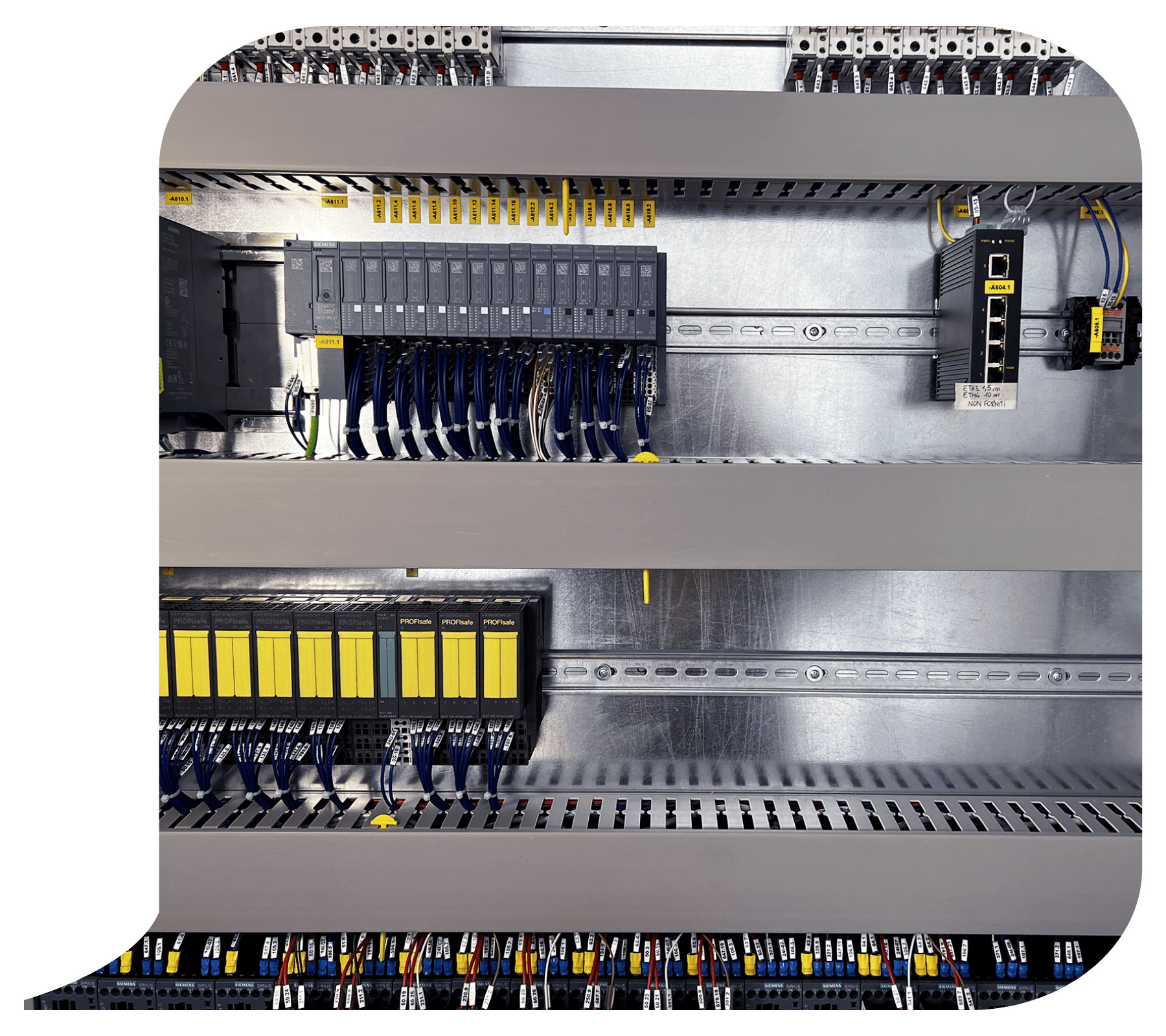

We are able to support customers in all phases, from the choice of components to design with advanced tools. Thanks to our long experience and expertise in various industrial sectors, BDF Digital offers tailor-made solutions, including:

- AC-DC and DC-DC control panels

- Motor control systems

- PLC/HMI application software

- Predictive maintenance systems

- Monitoring and air conditioning systems

- Data logging

- Process analysis

- SCADA

- HMI interfaces

- Capability solutions.

Choose BDF Digital for scalable and innovative solutions, capable of optimizing your production processes and responding to the challenges of industrial digitalization.

SOME SOLUTIONS

SOLUTIONS FOR GLASS

Thanks to its many years of experience, BDF Digital has acquired a prestigious know-how that allows the R&D department to develop top-level solutions for hollow and pressed glass production machines.

From Melting to Forming, we provide an advanced system capable not only of optimising production time and quality, but also consumption thanks to our regenerative solutions.

For this sector, we have developed a complete system consisting of several PLCs synchronised with one another in order to coordinate the various operations performed by the machine, delegating the control of the individual movement functions to the integrated intelligence in the drives.

SOLUTIONS FOR PLASTIC INJECTION MACHINES (PLASTIC APPLICATION)

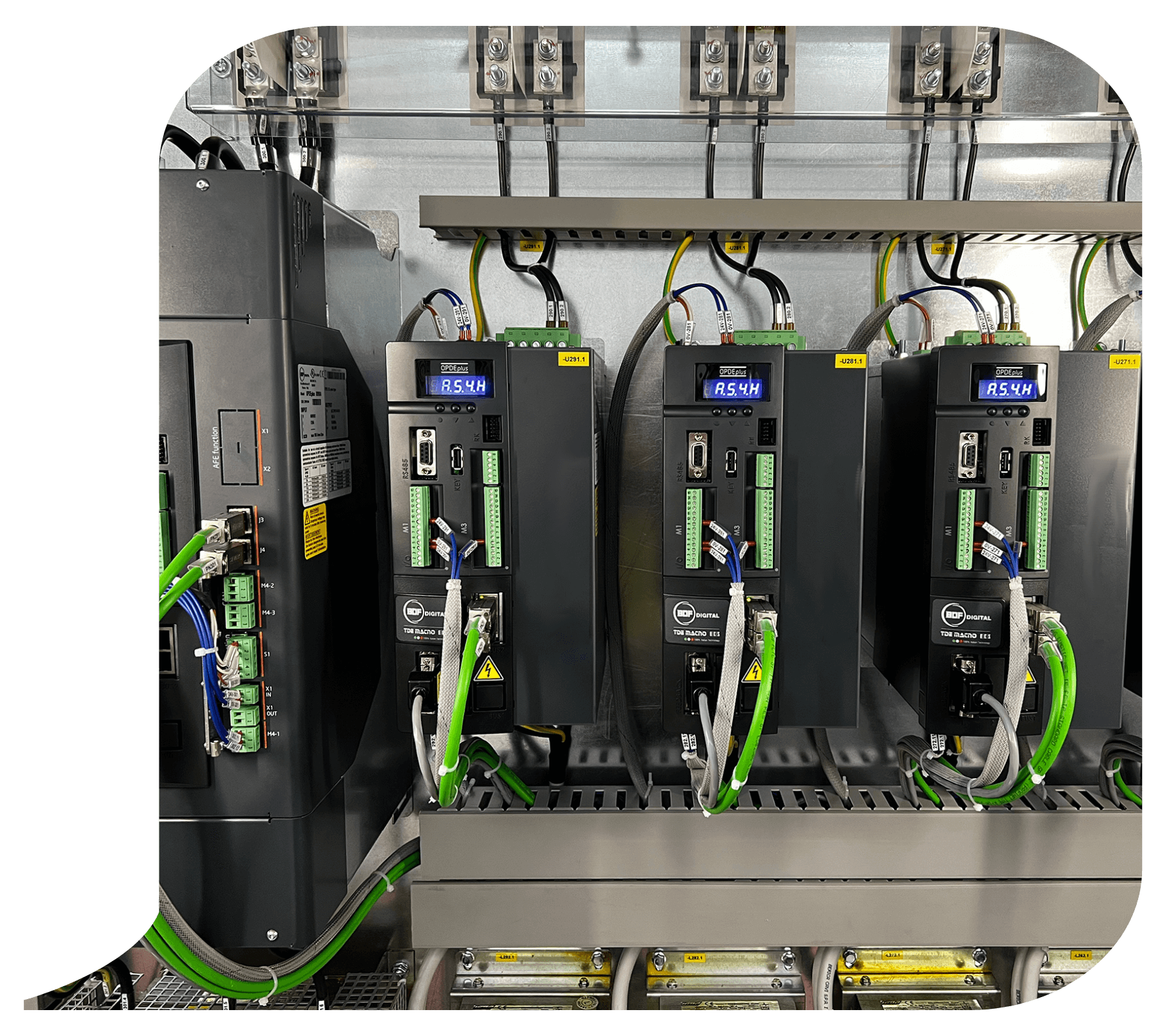

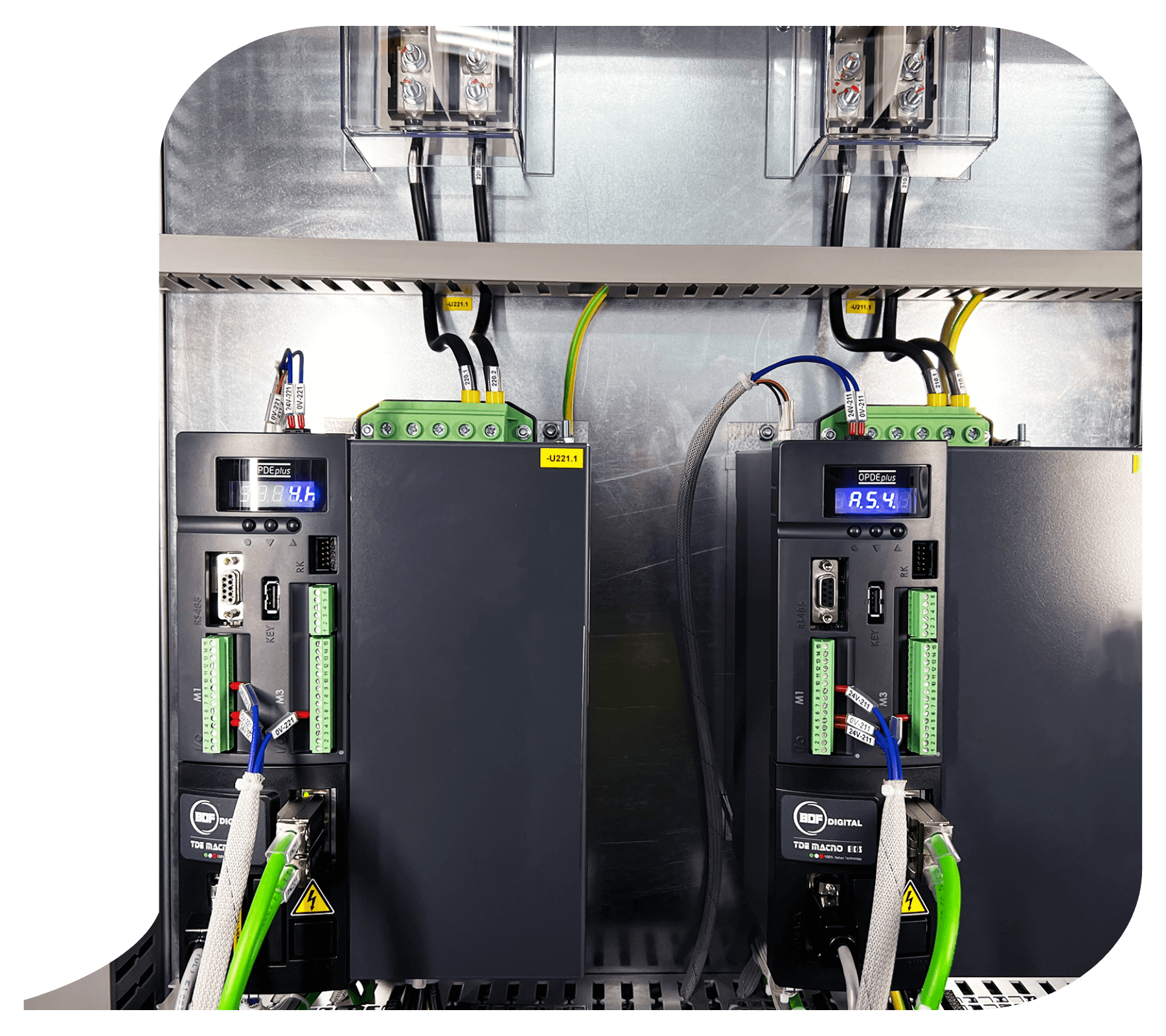

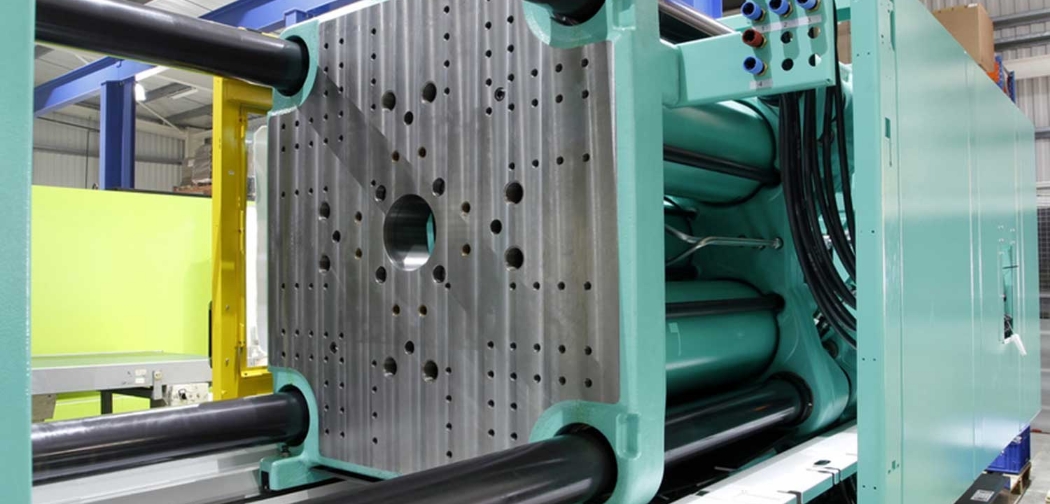

Bdf Digital has many years of experience in drive systems for the plastics sector, from extruders to injection moulding machines (hybrid and full electric) all the way to blow moulding machines. Customers can count on our experts’ flexibility when it comes to creating customised drive systems, tailored to the customer’s needs.

In hybrid presses, the OPDEplus servo drive controls the servo pump and adjusts the speed profiles. The digital connection between the servo pump, the drives and the proportional valves ensures efficient and fast communication with the press control. In full electric presses, the OPDEplus drive is the real star of machine control, thanks to the application functions developed within the drive.

SOLUTIONS FOR FLEXOGRAPHIC PRINTING

Over the years, BDF Digital has developed innovative technology for drive systems in the flexographic printing sector, for various applications, both for the central drum machine, with real axis, and for the stack machine, with virtual axis. In this case, one of the counter pressers can easily be defined as “master” and will send the reference to the other axes that will follow it.

Over the years, BDF Digital has developed innovative technology for drive systems in the flexographic printing sector, for various applications, both for the central drum machine, with real axis, and for the stack machine, with virtual axis. In this case, one of the counter pressers can easily be defined as “master” and will send the reference to the other axes that will follow it.

Over the years, BDF Digital has developed innovative technology for drive systems in the flexographic printing sector, for various applications, both for the central drum machine, with real axis, and for the stack machine, with virtual axis. In this case, one of the counter pressers can easily be defined as “master” and will send the reference to the other axes that will follow it.

SOLUTIONS FOR METAL

BDF Digital offers a design and manufacturing service for the metal processing sector: unwinders, strip accumulators, pipe welding, cutting units and pipe handling, all able to meet the customer’s requirements.

Our solutions range from simple open-loop control for material handling to closed-loop control for cutting lines and servo control for high cutting precision.

Thanks to the know-how acquired by our R&D department, BDF Digital creates customised solutions in areas of application requiring special properties: something that standard technology would not be able to do.

SOLUTIONS FOR THE MARINE SECTOR

With its marine solutions, BDF Digital meets the need for optimised performance and achieves optimum eco-efficiency.

Our know-how in the field of automation and renewable energy allows us to create customised solutions for power generation and distribution on ships and yachts.

In addition to this, we offer the PMS – Power Management System – integrated with the drive system, by means of high-speed digital communication with protection devices and controllers. Thanks to this system, BDF Digital guarantees full control, on board, of the energy storage, load control and propulsion control solution.

SOLUTIONS FOR CRANES

BDF Digital offers a design and manufacturing service for the Crane sector:

- Lifting

Integrated functions for Master/Slave synchronisation (torque, position, current)

Brake control (torque storage)

Speed and overspeed control

- Trolley/Bridge

Speed synchronism contro

- Crane rotation

Synchronism and trigonometric functions

- Lifting/synchronisation

Tandem Hoist.

Pos/Sp synchronisation with CAN D2D + PWM synchronisation in HW or with SYNC from Ethercat/Profinet

Our know-how allows us to create customised solutions for the world of cranes and overhead cranes.

SCADA – MONITORING AND SUPERVISION SYSTEM

Thanks to its know-how and its Technical Department, BDF Digital has designed and developed a CMS – Condition Monitoring System – capable of identifying correct maintenance times. Thanks to this system, we can guarantee greater efficiency and productivity of the production system, reducing operating and service costs for the customer.

APPLICATIONS

Search for your production sector and find out what we have to offer.

CUSTOMSOLUTIONS

CONTACT US!

Haven’t found what you were looking for? Contact us!