Numerical control ideal for marble and stone processing

Equipped with a versatile, high-performance architecture, it can be used in many areas of application. The CNC has a modular structure, it can manage several fieldbuses and it can control multiple drives and local and remote input/output interfaces. Thanks to advanced algorithms, BDF Digital’s numerical control can control movement with maximum speed and precision, thus adapting to any type of machine tool. It therefore becomes an ideal component for industry 4.0, perfectly integrating into any company communication network.

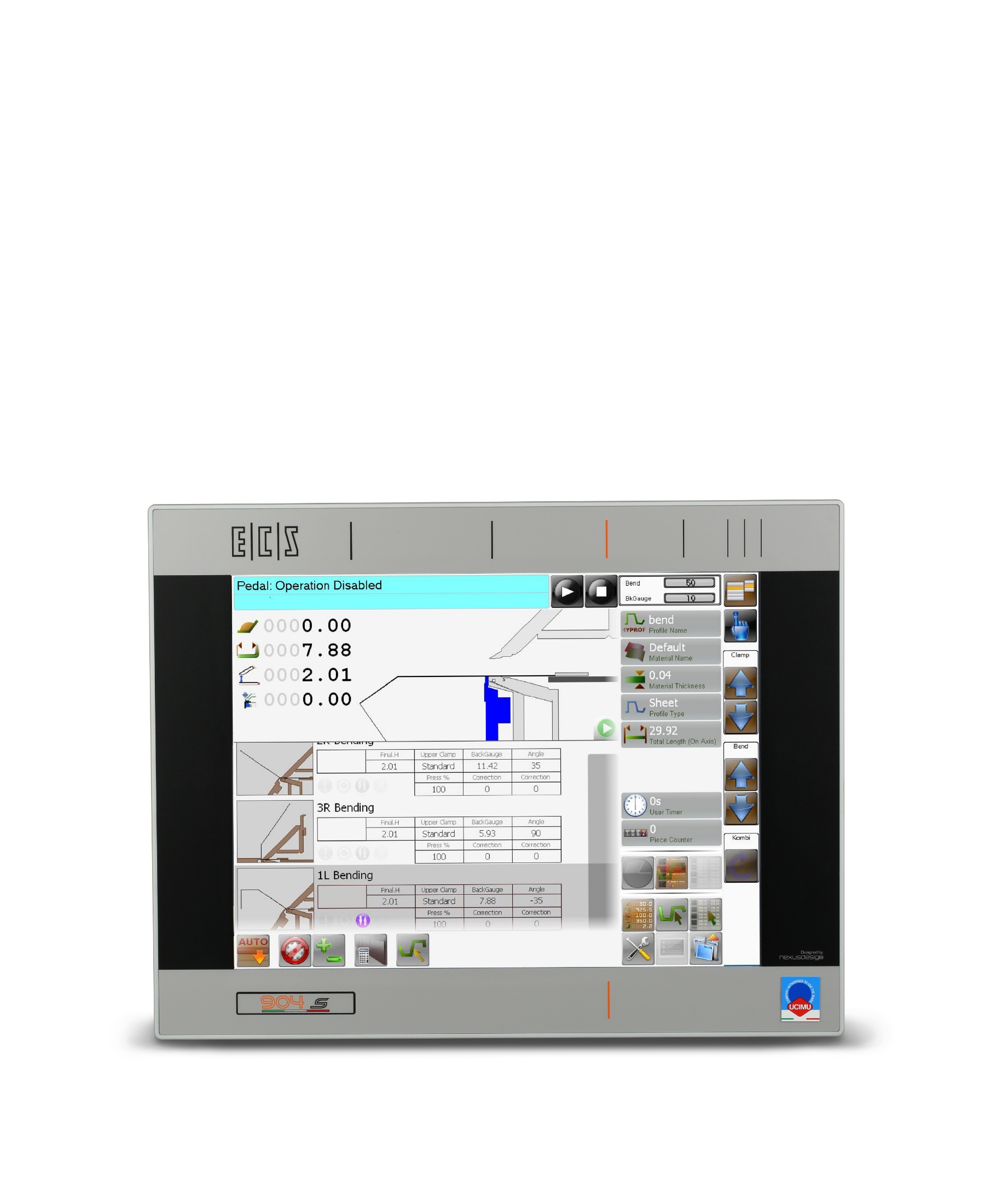

In addition to this, the CNCs are compatible with various devices available on the market (I/Os, laser sources, focusers, etc.) and they are very easy to retrofit to all previous ECS systems and third-party numerical controls.

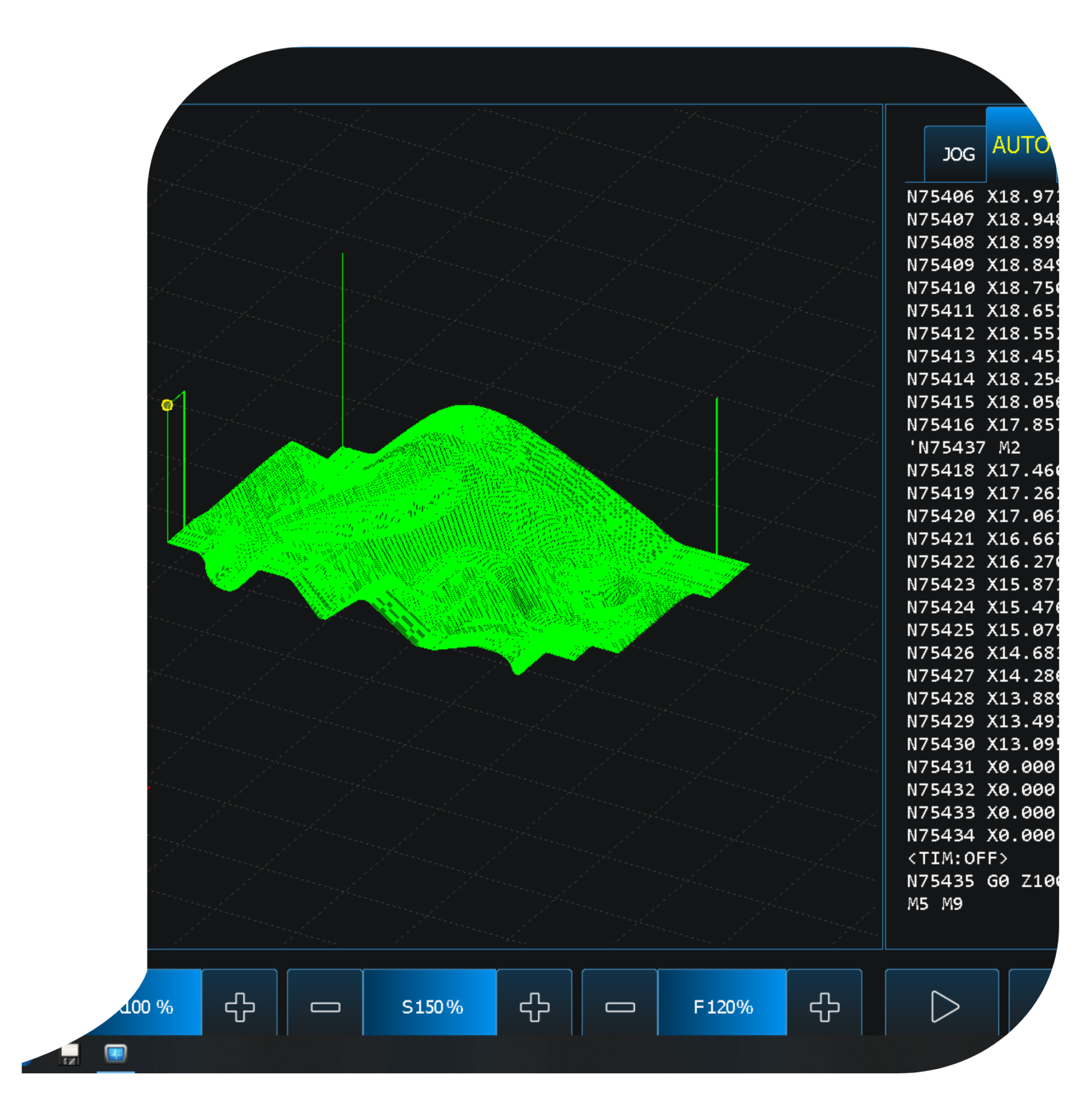

The CNC1011, thanks to its interface specifically designed for touch screens, combined with a modular APP-based software architecture, allows for the features installed on the CNC to be segmented, turning it into the perform numerical control for marble and stone processing machines. In particular, it was designed to control 3, 4 and 5-axis bridge milling machines; the operator can manage the entire machining process on board the machine, starting from importing the drawing, digitising the slab with the camera, positioning the cuts according to the veins, cutting the slab (also with automatic nesting), up to 3D machining with a cutting disc (with finishing cycles).

Choose your model to request information

Different keyboards available

Alphanumeric: membrane (heavy-duty) or long-stroke (ergonomic)

Machine: membrane version, available with different layouts (handwheel, joystick)

Machine push-button panel: modular with industrial buttons, available with different layouts (handwheel, joystick)

Fieldbus connectivity: EtherCAT (integrated), BDFLINK (gateway), Mechatrolink® 2 (gateway), SERCOS (gateway)

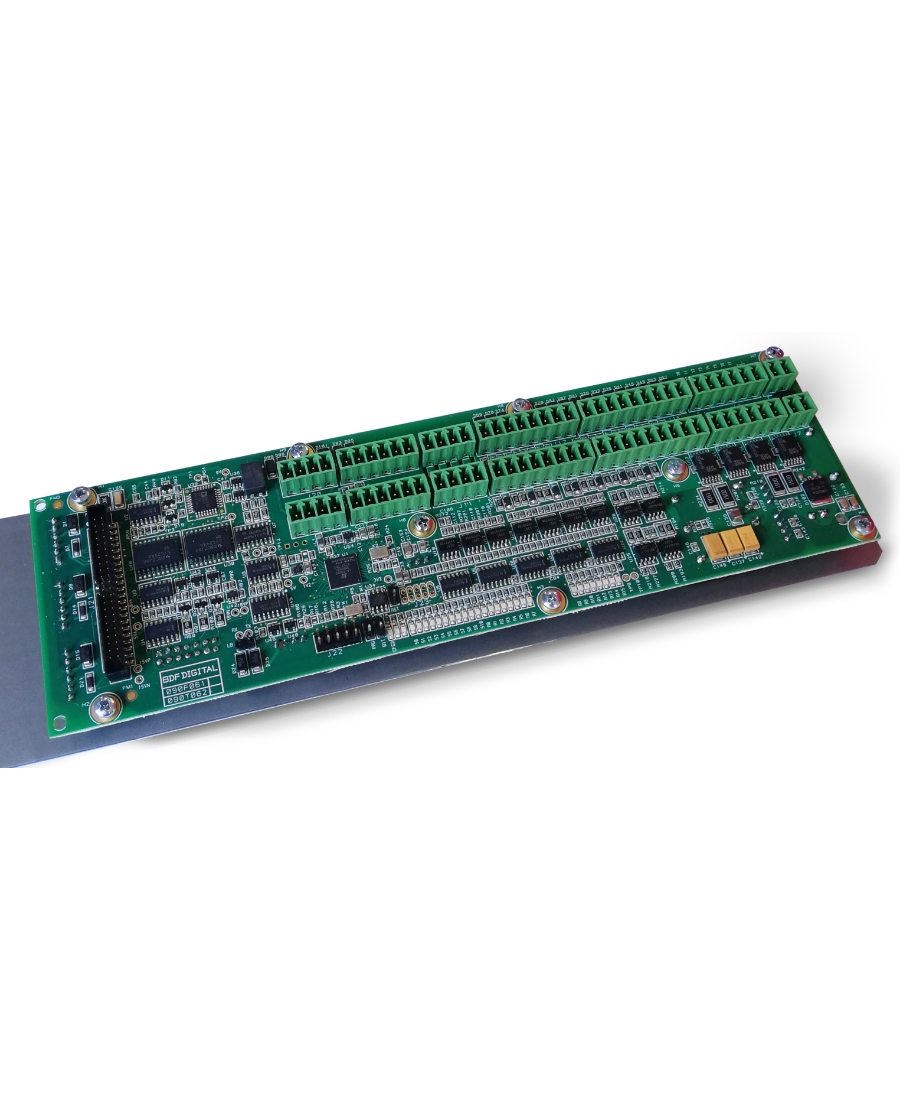

Analogue and digital interfaces (up to 2048 I/Os): via EtherCAT modules

Drive control in speed or position loop

Management of gantry and tandem axes (electrical backlash)

CNC900PC simulator: allowing for realistic machine simulation. A useful tool for the manufacturer, to fine-tune the application (PLC and machine data) without having the real CNC. It also allows the machine operator to check machining off-line, which is ideal for training and instructing personnel

CNC and/or PLC data export, configurable according to the customer’s needs, for data exchange with external management systems (MES, ERP)

RB900Studio software: making it possible to customise the pages already provided by default, or add new ones, in order to create a completely customised HMI.