Powerquality

Systems for Energy Efficiency Improvement

Power quality refers to all the electrical characteristics of power that influence the proper functioning of electrical devices and systems.

It concerns the reliability and the degree to which the supplied power matches the rated values required by electrical equipment and systems.

A Power Quality problem typically involves a deviation from ideal power supply conditions in terms of voltage or frequency.

Poor Power Quality inevitably causes issues for motors, drive systems, lighting installations, and IT networks.

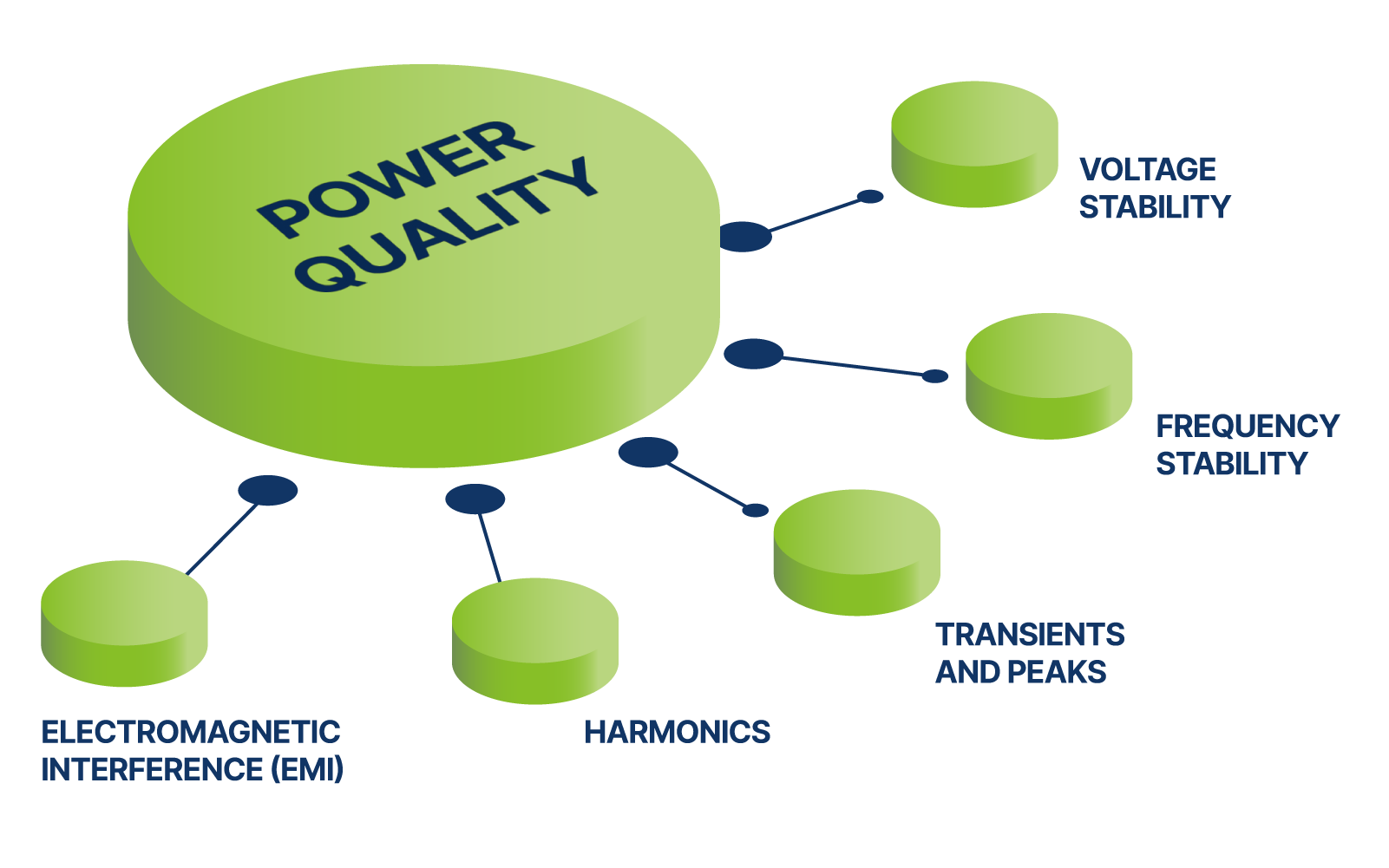

Power quality includes many aspects, but the main factors are:

- Voltage Stability: the supply voltage must remain within a defined variability range, changing its value smoothly and without interruptions.

- Frequency Stability: the frequency of the power grid must stay within a defined variability range, changing smoothly and without interruptions (typically 50 Hz or 60 Hz, depending on the region).

- Harmonics: waveform distortions in the current caused by non-linear equipment.

- Transients and Spikes: sudden increases (spikes) or drops (sags) in voltage that can damage electronic devices.

- Electromagnetic Interference (EMI): electrical disturbances that spread and interfere with the operation of other devices.

Good power quality is essential for the proper operation and longevity of electrical equipment, especially sensitive devices like computers, industrial systems, and communication equipment. Poor power quality can lead to failures, malfunctions, or reduced efficiency.

Poor power quality can have several negative consequences, both at the level of individual devices and for industrial systems or in broader contexts.

Here are some of the main issues caused by low electrical power quality:

Overheating: Voltage fluctuations or sudden spikes can cause temperature increases in electronic components, leading to malfunctions or premature failures. Current harmonics cause additional losses in transformers, resulting in higher operating temperatures and a consequent reduction in the machine’s service life.

Damage to Electronic Boards: Harmonics or overvoltages can irreparably damage integrated circuits and other sensitive electronic components.

Mechanical Failures: In motors and electrical machines, voltage fluctuations and waveform distortions can lead to vibrations and abnormal wear, shortening the equipment’s operational lifespan.

Service Interruptions: Voltage sags or blackouts, even if brief, can disrupt production processes, cause data loss, or lead to malfunctions in electronic and IT systems.

Malfunctions in Control Systems: Automated systems, such as industrial automation controls, may not operate correctly, potentially compromising production or causing complete shutdowns of facilities.

Computer Crashes and Data Loss: Voltage fluctuations or electrical noise can cause IT equipment to malfunction, leading to software crashes or the loss of valuable data.

High Maintenance Costs: Equipment damaged due to poor power quality requires more frequent maintenance or replacement, leading to increased operational expenses.

Reduced Efficiency: Low power quality can decrease the efficiency of electrical equipment, as devices may operate under suboptimal conditions, resulting in higher energy consumption.

Penalties: In some cases—especially in industrial settings—poor power quality can lead to fines or penalties from energy providers if the system fails to meet certain quality standards.

Fire Hazard: Overvoltages or short circuits caused by voltage spikes can significantly increase the risk of electrical fires, especially if equipment is not properly protected.

Risk of Personal Injury: Electrical malfunctions or failures can, in some cases, pose safety hazards or cause injuries to operators and users.

Communication Disturbances: Electromagnetic interference (EMI) can affect signal quality in telecommunications systems, causing disruptions in data transmission or telephone lines.

Problems in IT Systems: Power disturbances can also cause malfunctions in servers, network devices, or IT infrastructure, compromising service quality and slowing down connectivity.

Reduced Service life: The presence of voltage distortions or harmonics can shorten the overall level of electrical and electronic equipment, as operating under non-optimal conditions accelerates wear and tear.

In summary:

Poor electrical power quality can not only directly damage equipment and shorten its service life but also cause service disruptions, increase operating costs, and, in more severe cases, pose safety risks.

For these reasons, it is important to monitor and improve power quality, especially in industrial environments and critical infrastructure.

In summary:

Poor electrical power quality can not only directly damage equipment and shorten its service life but also cause service disruptions, increase operating costs, and, in more severe cases, pose safety risks.

For these reasons, it is important to monitor and improve power quality, especially in industrial environments and critical infrastructure.

Advantages of the AHF Solution

- Dynamic Power Factor Correction

- No Resonance Phenomena:

The use of passive filters introduces the risk of resonance events, which cause high currents or voltages that can damage equipment. The active filter detects the onset of such conditions and corrects them, preventing this phenomenon. - Compact, Suitable for Harsh Environments (humidity and environmental pollution)

- Integrated and Efficient Solution

- Designed for Easy Maintenance with few spare parts and reduced downtime

- Lower Operating Expenses and Total Cost of Ownership

APPLICATIONSECTORS

- Water and wastewater treatment

- Marine industry

- Oil, gas, and mining industries

- HVAC industry

- Airports

- Hospitals

- Revamping of industrial plants with power factor and harmonic distortion issues

APPLICATIONSECTORS

- Water and wastewater treatment

- Marine industry

- Oil, gas, and mining industries

- HVAC industry

- Airports

- Hospitals

- Revamping of industrial plants with power factor correction and harmonic distortion issues

AHF Plus – ActiveHarmonic Filter

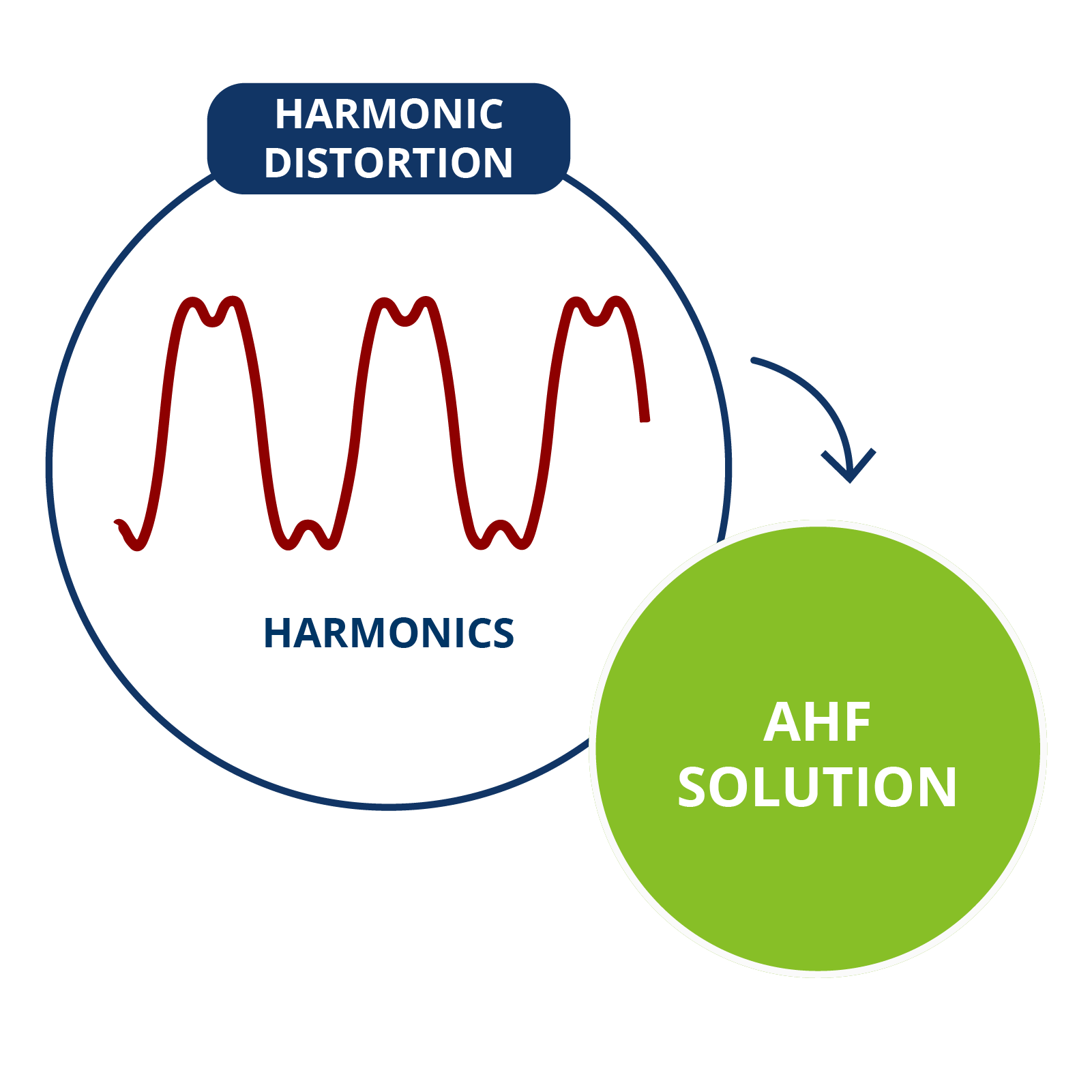

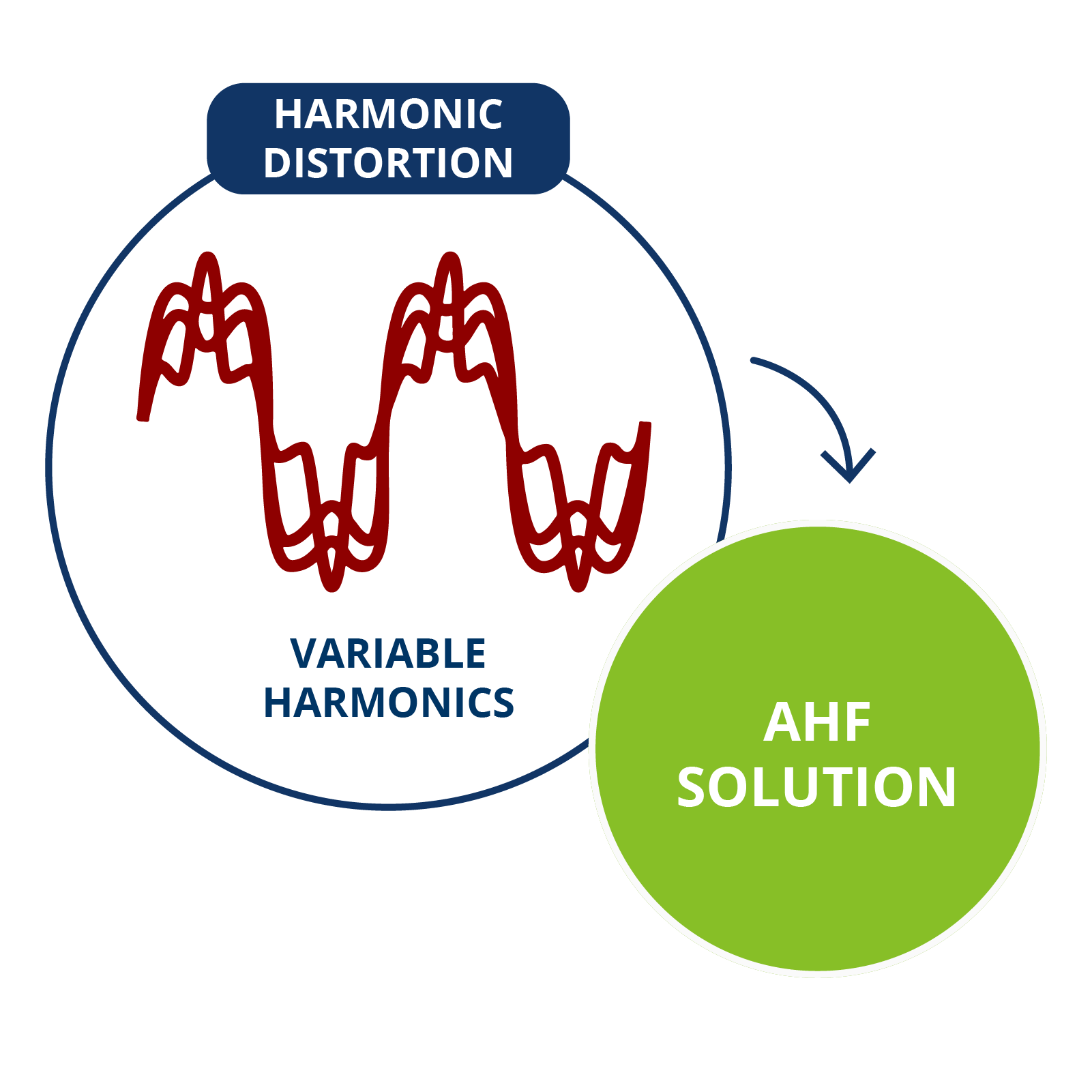

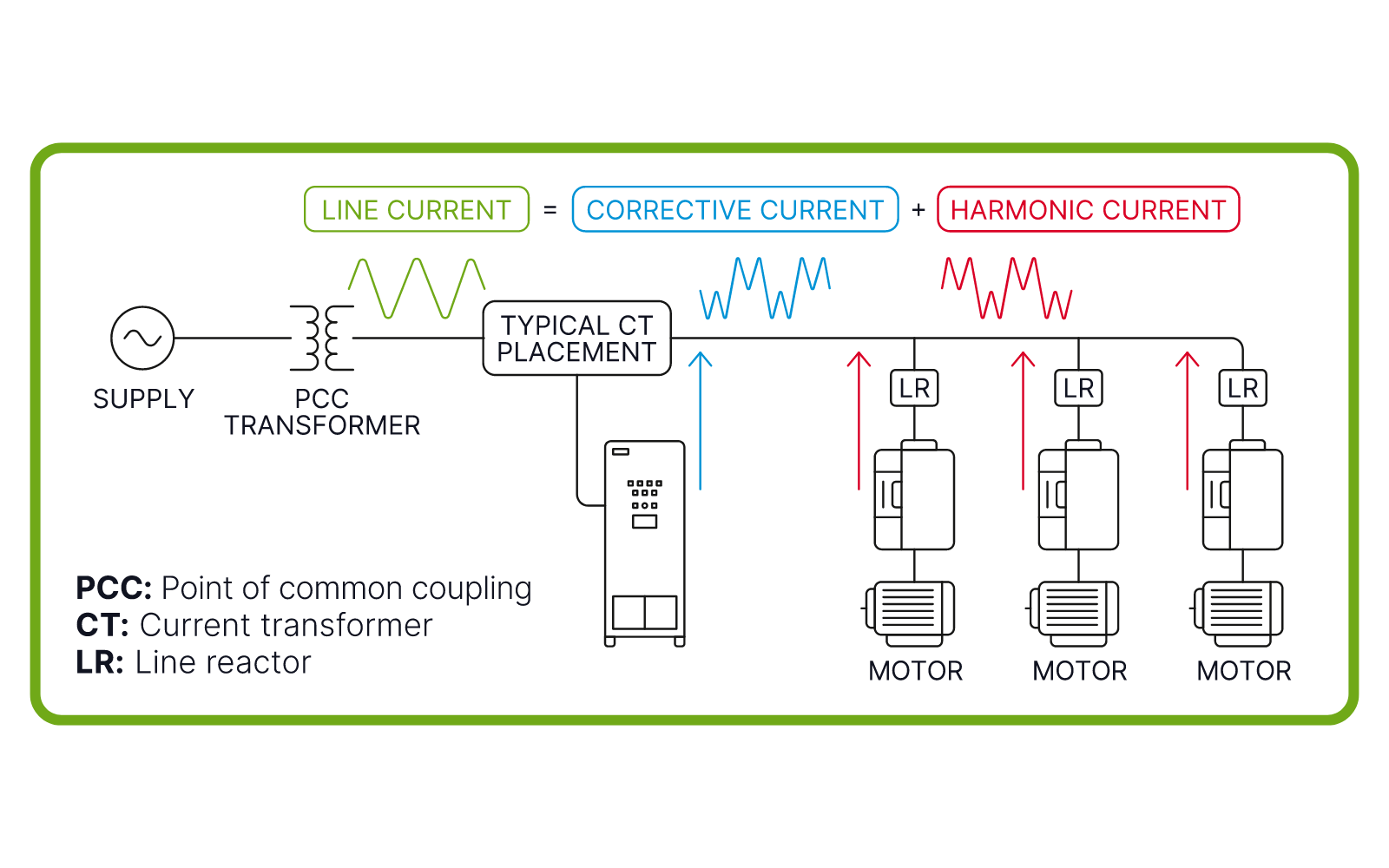

A filter designed to reduce harmonic distortions caused by frequency converters.

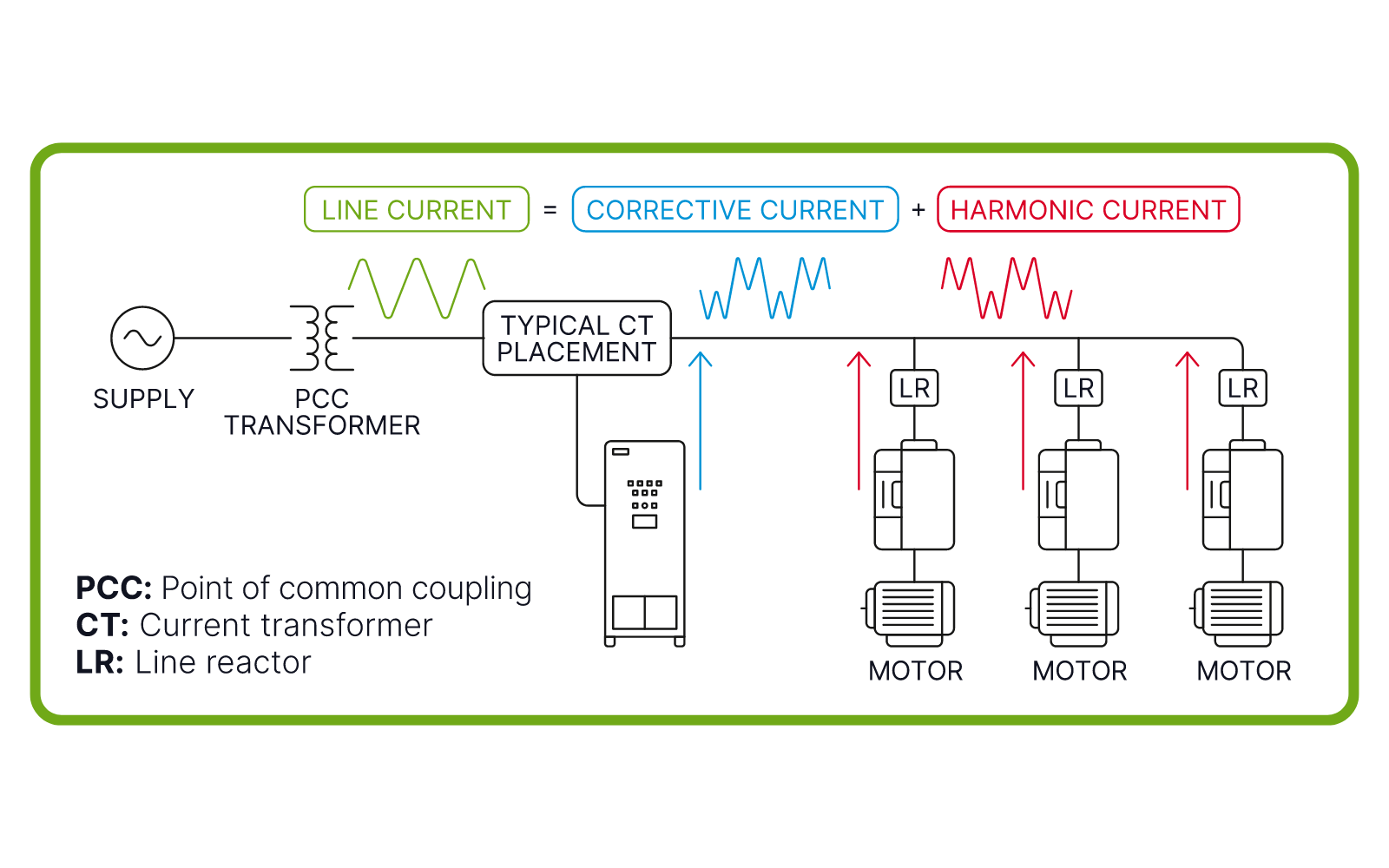

AHF Plus ensures sinusoidal current absorption and a unitary power factor from the grid, even in the presence of nonlinear loads.

Harmonics are voltages and currents containing frequency components that pollute the sinusoidal waveform in an AC circuit, distorting the main voltage. BDF Digital offers the ability to solve unbalance with its innovative filter, detecting the harmonics present on the power line and generating waveforms that counteract and cancel out the unwanted harmonics.

FEATURES

- Compensation of current harmonics from nonlinear loads up to the 17th harmonic (depending on hardware size and application requirements)

- Resonance control: detection and mitigation

- Reactive power generation and power factor correction (cos φ ≃ 1)

- Quick commissioning with plug-and-play functionality and easy parameterization via OPDExplorer software

- Easy adaptation to existing installations, especially when harmonic distortion increases with the addition of nonlinear loads

- Power factor correction

- Simple maintenance that reduces downtime and costs

- Highly efficient and robust, ensuring long service life and low operating costs

- Short payback period

TECHNICAL DATA

- Main voltage (L1, L2, L3): Voltage range 3 x 380-480 V AC

- Current ratings: sizes XL (40-48-60A), BF1-BF2-BF3 (from 70 to 510A)

- Supply frequency: 50/60 Hz ±2%

- Compensation: Harmonic mitigation 2nd to 13th order

- Power factor correction

*Additional voltage ranges and filter currents are available upon request.

The HMI interface installed on the AHF Plus allows monitoring of the main parameters of interest (active power, reactive power, power factor, etc.), ensuring full transparency in assessing the effectiveness of the installed product.

- It enables viewing the general status of the product to evaluate the proper functioning of the system. You can check if the system is connected to the grid, its operational status, emergency or alarm conditions, and the temperature at which it is operating. Actual values for the grid, load, and AHF are also visible.

- In the power factor correction screen, it is possible to visualize reactive power balance between load, AHF, and the grid through diagrams, as well as the trend of apparent power. A vector diagram is also provided, which offers an immediate understanding of the system’s operating state, useful for distinguishing between running and stopped conditions.

- It allows displaying various alarms present in the system, aiming to simplify troubleshooting of any issues that may arise.

- It also provides a web-server interface to enable remote supervision of the AHF system’s operation.

Green Energy Generatione Power Quality

RELATED PRODUCTS

Case History

Contact us!

Haven’t found what you were looking for? Contact us!